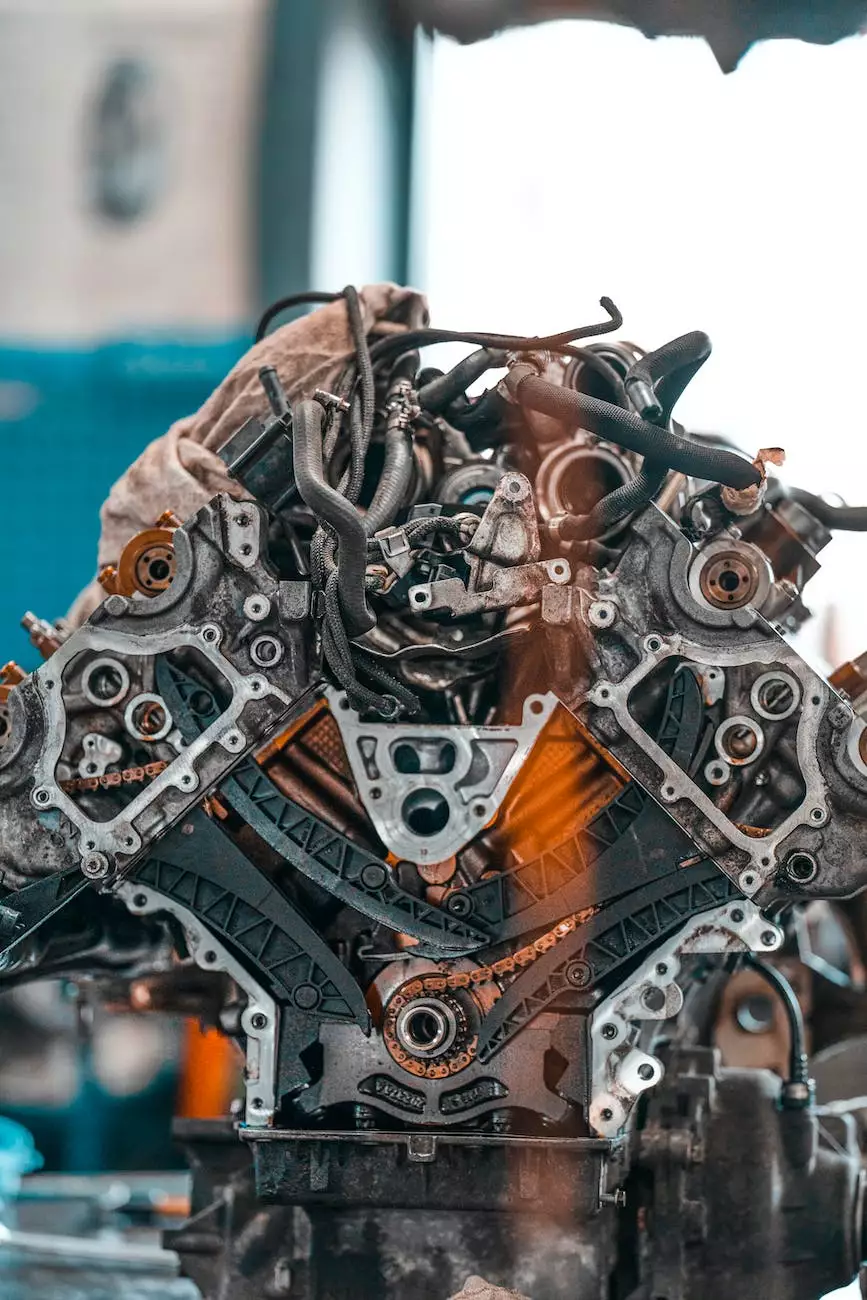

What Causes a Fuel Pump to Go Bad?

Auto Repair

When it comes to the proper functioning of a vehicle, the fuel pump plays a crucial role. Located in the fuel tank, the fuel pump ensures that the engine receives a continuous and reliable supply of fuel. However, like any other automotive component, fuel pumps can encounter issues and go bad over time. Understanding the factors that contribute to a fuel pump's failure can help vehicle owners prevent potential problems and ensure the optimal performance of their vehicles.

Fuel Quality

The quality of fuel is one of the primary factors that can affect the lifespan of a fuel pump. Contaminated or poor-quality fuel contains impurities that can damage the pump, leading to its premature failure. These impurities include dirt, debris, water, and even rust particles. It is essential to use high-quality fuel from reputable sources to ensure the longevity of your fuel pump.

Fuel Pump Overheating

Excessive heat can also contribute to the deterioration of a fuel pump. When the fuel pump operates at higher temperatures for extended periods, the internal components can become damaged or weakened. Factors such as a clogged or restricted fuel line, a malfunctioning cooling system, or prolonged continuous use can lead to fuel pump overheating. Regular maintenance and inspections can help identify any issues with the vehicle's cooling system and prevent overheating-related fuel pump failures.

Fuel Contamination

In addition to poor-quality fuel, contaminants present in the fuel system can also cause fuel pump failure. Over time, sediments, dirt, and other debris can accumulate in the fuel tank, clogging the fuel filter and eventually reaching the fuel pump. These contaminants can obstruct the fuel flow, strain the fuel pump, and eventually damage its delicate components. Regular fuel system maintenance and filter replacements are essential to prevent contamination-related fuel pump failures.

Electrical Issues

The fuel pump relies on an electrical system to function properly. Issues with the electrical components can disrupt the fuel pump's operation and cause it to go bad. Problems such as wiring defects, faulty relays, or even a malfunctioning fuel pump control module can lead to inadequate power supply or irregular voltage, placing excessive strain on the fuel pump. Regular electrical system inspections and prompt repairs can help prevent these issues.

Fuel Pump Age and Wear

Like any mechanical component, fuel pumps have a finite lifespan. Over time, the continuous operation, exposure to different fuel conditions, and normal wear and tear can lead to the deterioration of the fuel pump's internal parts. A worn-out fuel pump will eventually fail, resulting in poor engine performance or the inability to start the vehicle. Regular inspections and timely fuel pump replacements are crucial to avoid unexpected failures and costly repairs.

Preventing Fuel Pump Failure

While fuel pump failures can be inconvenient and sometimes costly, certain preventative measures can help prolong the fuel pump's lifespan and minimize the chances of failure:

- Regular Maintenance: Adhering to the manufacturer's recommended maintenance schedule can help identify and address potential issues before they escalate.

- Using Quality Fuel: Opt for high-quality fuel from reputable sources to reduce the risk of fuel pump damage due to contaminants.

- Changing Fuel Filters: Regularly replacing fuel filters can prevent debris from reaching the fuel pump and causing damage.

- Cooling System Maintenance: Ensure your vehicle's cooling system is functioning correctly to prevent fuel pump overheating.

- Electrical System Checks: Regularly inspect and maintain the electrical components of your vehicle to avoid electrical issues that can affect the fuel pump.

By following these preventative measures and staying proactive in maintaining your vehicle's fuel system, you can help prolong the lifespan of your fuel pump and minimize the risk of unexpected failures.